随着社会经济的腾飞,建筑行业已步入高速发展的道路.在这个过程之中,会出现大量的建筑垃圾,其中包括大量的废弃混凝土.这些建筑垃圾对于自然环境和生态平衡具有巨大威胁,而且处理这些建筑垃圾也十分费时费力.因此,有必要将这些建筑垃圾重新再利用,这样不但可以保护生态环境,而且还能够有效地解决建筑垃圾的处理问题.将废弃的混凝土破碎后,进行洗涤和分类,再次利用旧骨料,用其部分或全部替代天然骨料,重新配制而成新混凝土,这种新混凝土称为再生混凝土[1].再生混凝土与普通混凝土相比,其力学性能和耐久性均较差[2].将再生混凝土填充到钢管中,通过钢管对于再生混凝土的约束作用来提高整体的力学性能,与此同时钢管自身的稳定性也得到了很大的提升,称这种新型的组合结构为钢管再生混凝土结构.

目前,国内外专家学者对于钢管再生混凝土结构进行了许多探索与试验,并且取得许多突破性的成果与结论[3-7].对于钢管混凝土理论计算的研究已经趋于成熟,而对于钢管再生混凝土的理论计算才刚刚开始.本文对钢管混凝土的计算方法进行修正,使其适用于圆钢管再生混凝土轴压短柱的计算.

1 有限元模型

1.1 钢材与再生混凝土的本构关系

钢材所采用的本构关系为二次流塑模型[8].再生混凝土采用文献[9]提出的本构关系模型,该模型在原混凝土本构模型的基础上,引入了再生骨料取代率影响曲率系数,以此来体现再生骨料取代率所带来的影响.

1.2 有限元模型的建立与验证

本文在文献[10]试验数据的基础上,使用有限元软件ABAQUS建立圆钢管再生混凝土短柱有限元模型.经验证,圆钢管再生混凝土轴压短柱的模拟结果与试验结果吻合较好,表明本文所建立的ABAQUS有限元模型可以较好地模拟圆钢管再生混凝土轴压短柱的受力过程.

2 修正圆钢管再生混凝土轴压短柱承载力公式

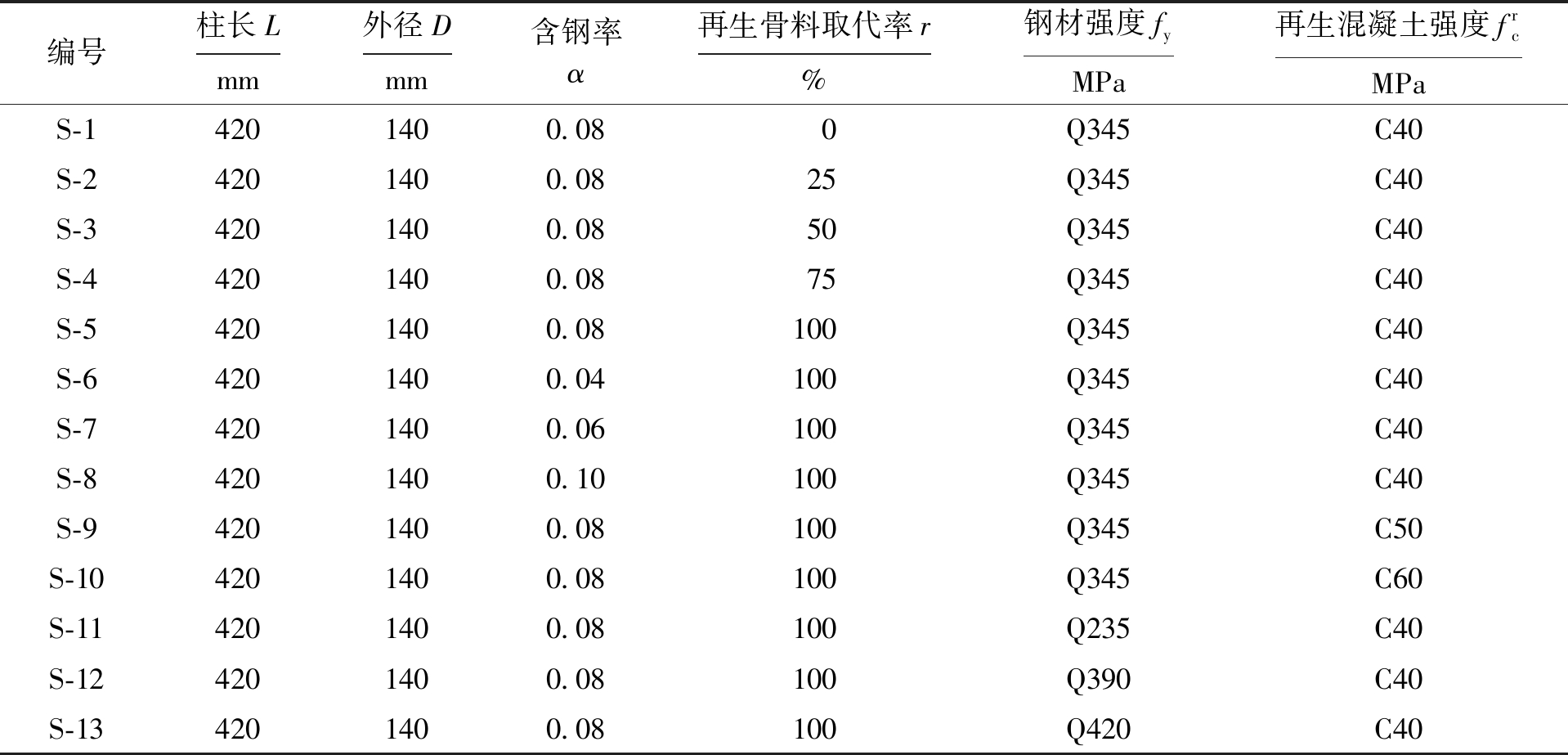

设置柱长L=420 mm,外径D=140 mm,与此同时取不同的再生骨料取代率、不同的含钢率、不同的再生混凝土强度和不同的钢材强度为变化参数,建立圆钢管再生混凝土轴压短柱模型,构件参数如表1所示.

表1 构件参数表

Tab.1 Specimen parameters

编号柱长Lmm外径Dmm含钢率α再生骨料取代率r%钢材强度fyMPa再生混凝土强度frcMPaS-14201400.08 0Q345C40S-24201400.0825Q345C40S-34201400.0850Q345C40S-44201400.0875Q345C40S-54201400.08100Q345C40S-64201400.04100Q345C40S-74201400.06100Q345C40S-84201400.10100Q345C40S-94201400.08100Q345C50S-104201400.08100Q345C60S-114201400.08100Q235C40S-124201400.08100Q390C40S-134201400.08100Q420C40

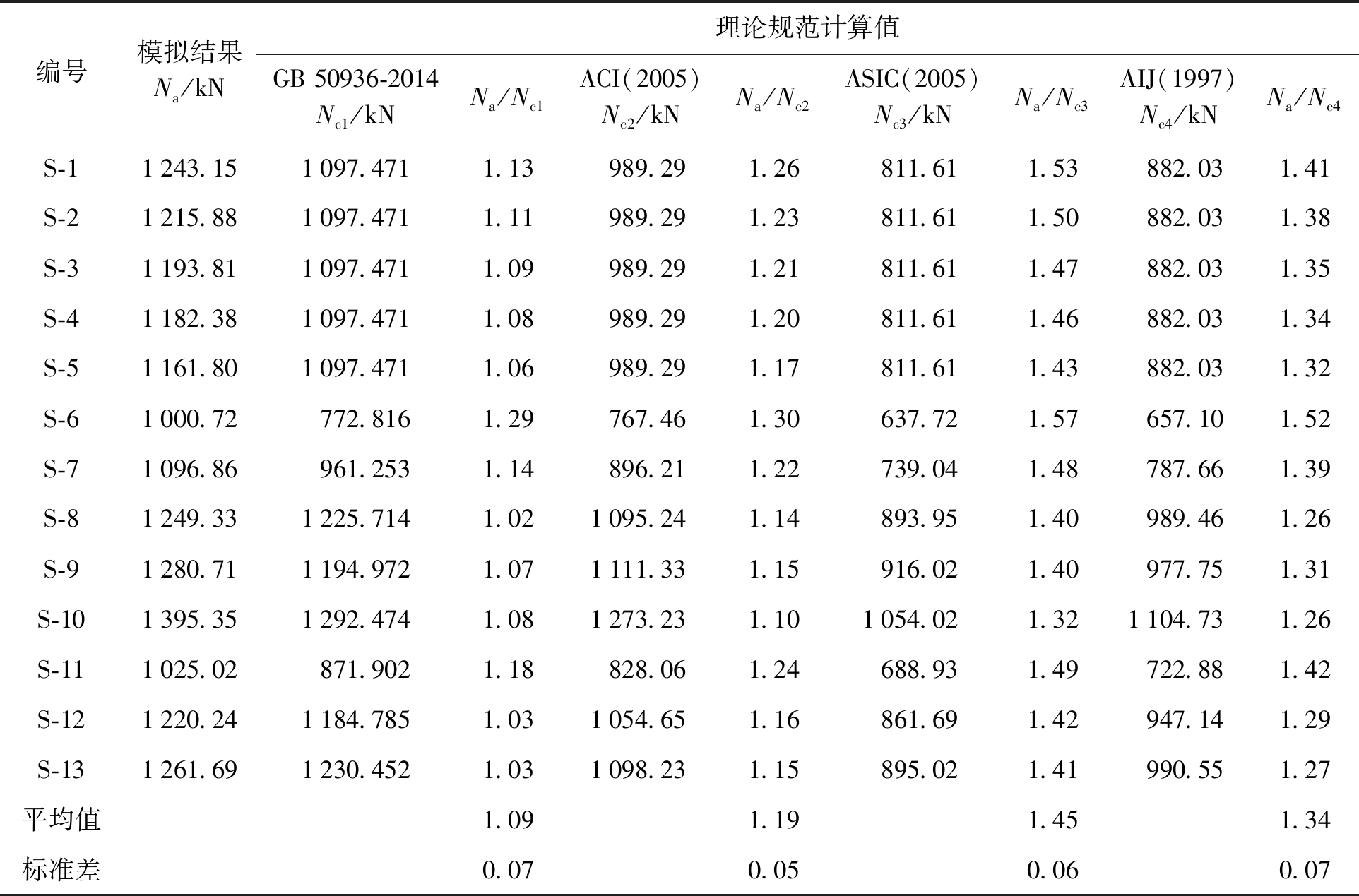

2.1 模拟结果与各规范计算结果对比

表2为规范计算结果与模拟结果对比.由表2可知,使用统一强度理论的规范(GB 50936-2014)[11]计算结果比模拟值小约10%,而使用拟混凝土理论规范ACI(2005)计算结果比模拟值小10%~30%,使用拟钢理论规范ASIC(2005)计算结果比模拟值小40%~50%,使用叠加理论规范AIJ(1997)计算结果则均比模拟值小30%~50%.使用拟混凝土理论规范ACI(2005)、拟钢理论规范ASIC(2005)、叠加理论规范AIJ(1997)的计算结果虽然处于安全范围,但是与模拟结果相差较大,精确度低.而使用规范《钢管混凝土结构技术规范》(GB 50936-2014)的计算结果不仅处于安全范围,而且精确度很高.因此,可采用规范《钢管混凝土结构技术规范》(GB 50936-2014)对钢管再生混凝土轴压短柱进行计算.

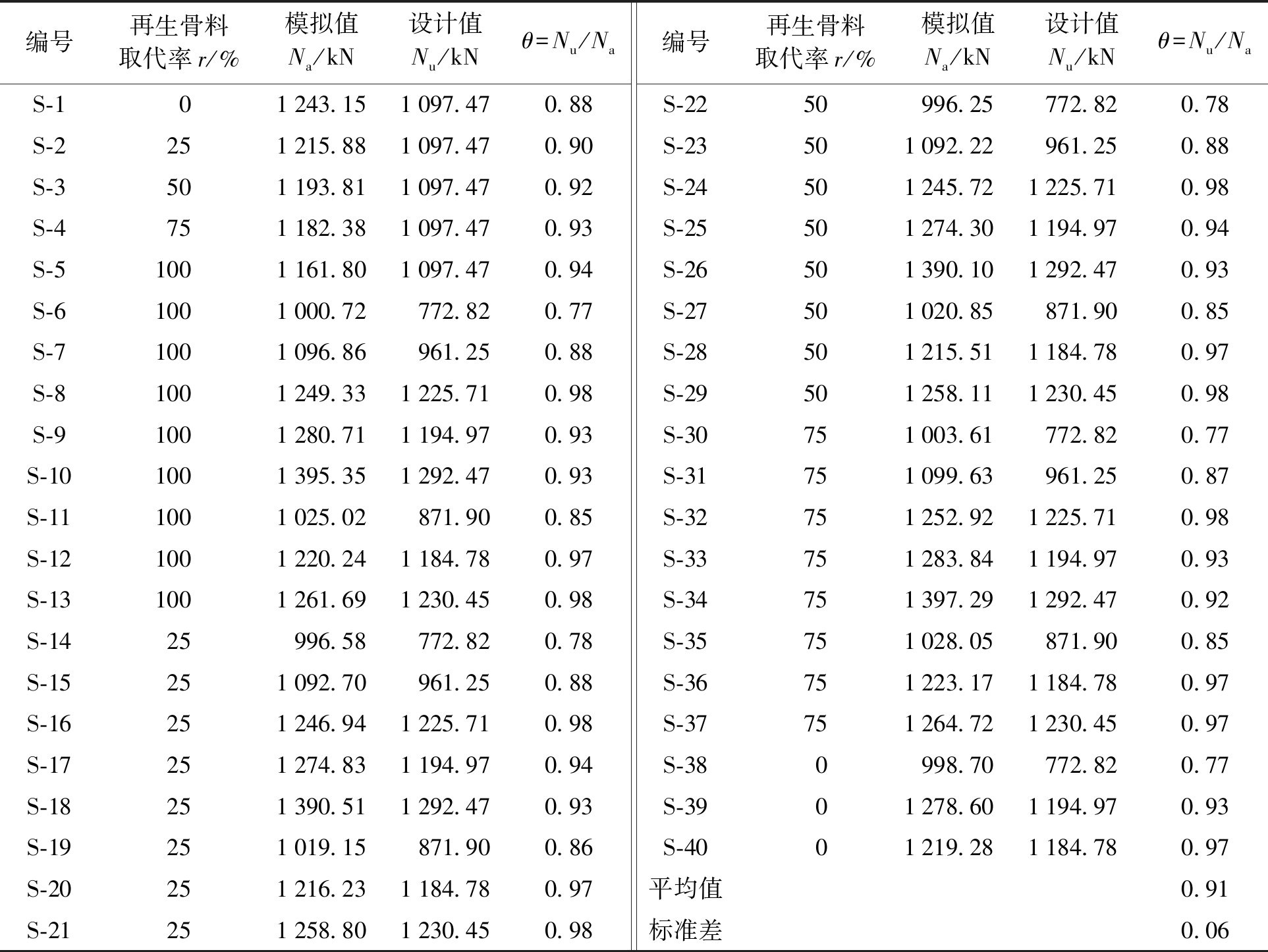

2.2 计算公式的修正

表3为θ值计算结果.再生骨料取代率对于圆钢管再生混凝土轴压短柱的极限承载力具有一定程度的影响.因此,在圆钢管再生混凝土轴压短柱承载力的计算公式中,应当包含再生骨料取代率这个影响因素.而现行规范《钢管混凝土结构技术规范》(GB 50936-2014)对于钢管再生混凝土轴压短柱具有较好的适用性,但是没有考虑再生骨料取代率对于其承载力的影响.因此,对于规范《钢管混凝土结构技术规范》中的钢管混凝土轴压短柱公式进行修正.在上述模拟结果的基础上,再对27根圆钢管再生混凝土轴压短柱进行模拟分析.通过设立参数θ,分析比较圆钢管再生混凝土短柱在轴心受压状态下的承载力模拟值Na和设计值Nu,结果如表3所示.

表2 规范计算结果与模拟结果对比

Tab.2 Comparison between calculated results under specifications and simulation results

编号模拟结果Na/kN理论规范计算值GB 50936-2014Nc1/kNNa/Nc1ACI(2005)Nc2/kNNa/Nc2ASIC(2005)Nc3/kNNa/Nc3AIJ(1997)Nc4/kNNa/Nc4S-11243.151097.4711.13989.291.26811.611.53882.031.41S-21215.881097.4711.11989.291.23811.611.50882.031.38S-31193.811097.4711.09989.291.21811.611.47882.031.35S-41182.381097.4711.08989.291.20811.611.46882.031.34S-51161.801097.4711.06989.291.17811.611.43882.031.32S-61000.72772.8161.29767.461.30637.721.57657.101.52S-71096.86961.2531.14896.211.22739.041.48787.661.39S-81249.331225.7141.021095.241.14893.951.40989.461.26S-91280.711194.9721.071111.331.15916.021.40977.751.31S-101395.351292.4741.081273.231.101054.021.321104.731.26S-111025.02871.9021.18828.061.24688.931.49722.881.42S-121220.241184.7851.031054.651.16861.691.42947.141.29S-131261.691230.4521.031098.231.15895.021.41990.551.27平均值1.091.191.451.34标准差0.070.050.060.07

表3 θ值计算结果

Tab.3 Calculation results of θ values

编号再生骨料取代率r/%模拟值Na/kN设计值Nu/kNθ=Nu/NaS-101243.151097.470.88S-2251215.881097.470.90S-3501193.811097.470.92S-4751182.381097.470.93S-51001161.801097.470.94S-61001000.72772.820.77S-71001096.86961.250.88S-81001249.331225.710.98S-91001280.711194.970.93S-101001395.351292.470.93S-111001025.02871.900.85S-121001220.241184.780.97S-131001261.691230.450.98S-1425996.58772.820.78S-15251092.70961.250.88S-16251246.941225.710.98S-17251274.831194.970.94S-18251390.511292.470.93S-19251019.15871.900.86S-20251216.231184.780.97S-21251258.801230.450.98编号再生骨料取代率r/%模拟值Na/kN设计值Nu/kNθ=Nu/NaS-2250996.25772.820.78S-23501092.22961.250.88S-24501245.721225.710.98S-25501274.301194.970.94S-26501390.101292.470.93S-27501020.85871.900.85S-28501215.511184.780.97S-29501258.111230.450.98S-30751003.61772.820.77S-31751099.63961.250.87S-32751252.921225.710.98S-33751283.841194.970.93S-34751397.291292.470.92S-35751028.05871.900.85S-36751223.171184.780.97S-37751264.721230.450.97S-380998.70772.820.77S-3901278.601194.970.93S-4001219.281184.780.97平均值0.91标准差0.06

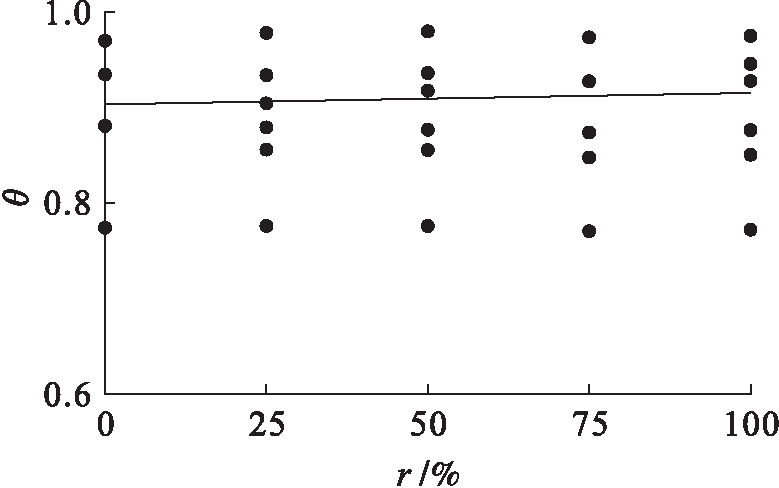

利用圆钢管再生混凝土轴压短柱模拟的数据,通过回归的方法,最终得到再生骨料取代率r与参数θ之间的关系,如图1所示.将表3中所有的θ值输入到软件Origin当中,经过软件Origin拟合后,得到再生骨料取代率r与参数θ之间的关系,其表达式为

θ=0.904+0.012r

(1)

因此,对钢管混凝土轴压短柱公式进行修改后,其表达式为

(2)

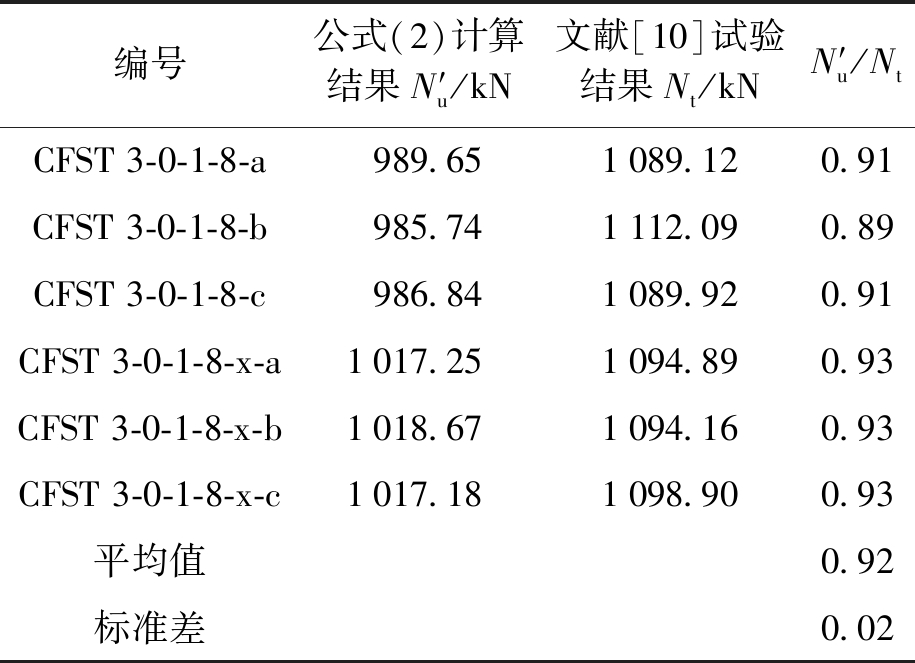

表4为公式(2)计算结果与文献[10]试验结果比较.由表4可知,平均值相差在10%以内,且标准差为0.02,同时计算结果偏于安全,表明拟合结果较好,公式(2)可用于钢管再生混凝土轴压短柱的计算.

图1 θ-r拟合曲线

Fig.1 Fitting curve of θ-r relation

3 结 论

本文通过分析得出以下结论:

1) 使用拟混凝土理论规范ACI(2005)、拟钢理论规范ASIC(2005)、叠加理论规范AIJ(1997)对于圆钢管再生混凝土轴压短柱的计算结果均比模拟值小,计算结果偏于安全,但是平均值相差均大于15%.

表4 公式(2)计算结果与文献[10]试验结果比较

Tab.4 Comparison between calculated results of formula (2) and test results of literature [10]

编号公式(2)计算结果N′u/kN文献[10]试验结果Nt/kNN′u/NtCFST 3-0-1-8-a989.651089.120.91CFST 3-0-1-8-b985.741112.090.89CFST 3-0-1-8-c986.841089.920.91CFST 3-0-1-8-x-a1017.251094.890.93CFST 3-0-1-8-x-b1018.671094.160.93CFST 3-0-1-8-x-c1017.181098.900.93平均值0.92标准差0.02

2) 虽然规范《钢管混凝土结构技术规范》(GB 50936-2014)计算结果平均相差在10%以内,计算结果也相对安全,但是此规范未考虑骨料取代率的影响.因此,对于规范中的公式进行修正,提出修正系数θ,使用修正后的公式(2)进行计算时,其计算结果偏于安全,而且精确度较高,适用于圆钢管再生混凝土轴压短柱承载力的计算.

[1]肖建庄.再生混凝土 [M].北京:中国建筑工业出版社,2008.

(XIAO Jian-zhuang.Recycled concrete [M].Beijing:China Architecture and Building Press,2008.)

[2]陈宗平,张士前,王妮,等.钢管再生混凝土轴压短柱受力性能的试验与理论分析 [J].工程力学,2013,30(4):107-114.

(CHEN Zong-ping,ZHANG Shi-qian,WANG Ni,et al.Analysis of mechanical behavior and bearing capacity of steel tube recycled concrete short columns [J].Engineering Mechanics,2013,30(4):107-114.)

[3]陈宗平,李良启,张向冈,等.钢管再生混凝土偏压柱受力性能及承载力计算 [J].土木工程学报,2012,45(10):72-80.

(CHEN Zong-ping,LI Liang-qi,ZHANG Xiang-gang,et al.Mechanical properties and bearing capacity calculation of concrete filled steel tubular short co-lumns under eccentric loading [J].China Civil Engineering Journal,2012,45(10):72-80.)

[4]张向冈,陈宗平,王讲美,等.钢管再生混凝土长柱偏压性能研究 [J].工程力学,2013,30(3):331-340.

(ZHANG Xiang-gang,CHEN Zong-ping,WANG Jiang-mei,et al.Study on the performance of recycled concrete filled steel tubular columns under eccentric loading [J].Engineering Mechanics,2013,30(3):331-340.)

[5]Chen Z P,Xu J J,Xue J Y,et al.Performance and calculations of recycled aggregate concrete filled steel tubes (RACFST) short columns under axial compression [J].International Journal of Steel Structures,2014,14(1):31-42.

[6]Hou C,Yang Y F.Behaviour and design calculations of recycled aggregate concrete-filled steel tube (RACFST) members [J].Magazine of Concrete Research,2015,66(11):611-620.

[7]Xiang X Y,Cai C S,Zhao R D,et al.Numerical ana-lysis of recycled aggregate concrete-filled steel tube stub columns [J].Advances in Structural Engineering,2016,19(5):717-729.

[8]韩林海.钢管混凝土结构![]() 理论与实践 [M].北京:科学出版社,2004.

理论与实践 [M].北京:科学出版社,2004.

(HAN Lin-hai.Concrete filled steel tube structure,theory and practice [M].Beijing:Science Press,2004.)

[9]李兵,张齐,孟爽.圆钢管再生混凝土短柱轴压承载力有限元分析 [J].沈阳建筑大学学报(自然科学版),2014,30(6):1037-1043.

(LI Bing,ZHANG Qi,MENG Shuang.Finite element analysis of recycled concrete filled circular steel tube short columns under axial compression [J].Journal of Shenyang Jianzhu University (Natural Science),2014,30(6):1037-1043.)

[10]马骥.圆钢管再生混凝土柱静力性能研究 [D].哈尔滨:哈尔滨工业大学,2013.

(MA Ji.Static behavior of recycled aggregate concrete filled circular steel tubular columns [D].Harbin:Harbin Institute of Technology,2013.)

[11]中华人民共和国住房和城乡建设部.GB 50936-2014钢管混凝土结构技术规范 [S].北京:中国建筑工业出版社,2014.

(Ministry of Housing and Urban-Rural Development of the People’s Republic of China.GB 50936-2014 Code for design of concrete filled steel tubular structure [S].Beijing:China Architecture and Building Press,2014.)