冷弯薄壁型钢墙体由C形和U形截面的冷弯薄壁型钢骨架和石膏板、OSB板、胶合板、钢板等墙面板,并通过自攻螺钉连接而成,形成了一个封闭的蒙皮结构[1].墙体为该结构体系的主要承重构件,承受重力荷载、风荷载以及水平地震作用引起的地震荷载.当墙板与钢骨架可靠连接时,墙面板在发挥围护作用的同时承担平面内的荷载,成为受力结构的一部分,参与整体结构体系共同工作,增加结构的刚度,提高墙体稳定性[2-5].国内外学者[6-7]进行了相关研究得出,钢框架对墙体承载力影响小,墙面板及螺钉间距对墙体承载力影响大,墙体尺寸对承载力影响小等.文献[8]提出了薄钢板覆面的墙体形式,试验研究了高宽比为2∶1至4∶1对墙体抗剪承载力的影响,基于大量墙体试验测试的结果,北美建筑规范AISI以表格形式提供抗剪强度设计值.一些研究人员对波纹钢板覆面的组合墙进行了试验研究,试验结果表明,相较于其他类型覆面墙体,波纹钢板覆面墙体具有更高的初始刚度和抗剪承载力,但延性较差.

1 组合墙体有限元模型

1.1 试件选取及材料特性

根据文献[9]数值计算结果和文献[8]试验结果,通过ABAQUS建立相同参数的组合墙体模型SWP-0,模型及材料参数如表1、2所示.墙架柱截面尺寸为C92.1 mm×41.3 mm×12.7 mm,导轨尺寸为U92.1 mm×41.3 mm;左右两端分别采用一根C形立柱连接固定;墙面板选用整块钢板,并与骨架采用自攻螺钉进行连接.

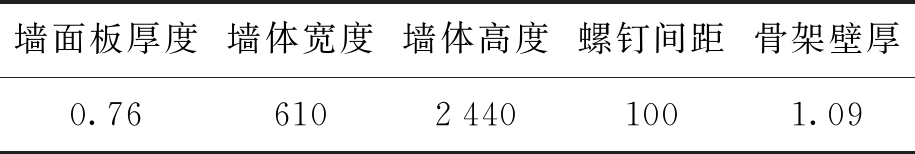

表1 模型参数

Tab.1 Model parameters mm

墙面板厚度墙体宽度墙体高度螺钉间距骨架壁厚0.7661024401001.09

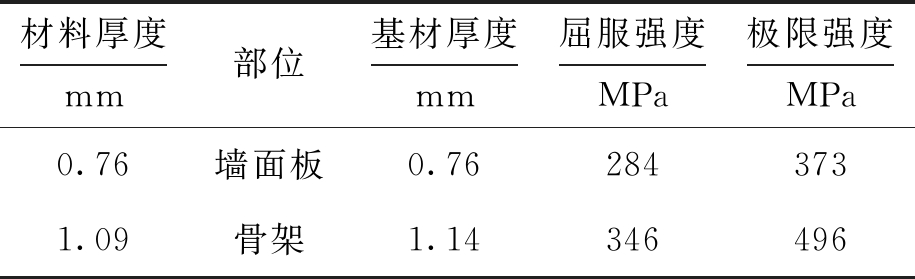

表2 材料参数

Tab.2 Material parameters

材料厚度mm部位基材厚度mm屈服强度MPa极限强度MPa0.76墙面板0.762843731.09骨架1.14346496

1.2 有限元模型单元选取

所有部件均采用S4R壳单元,采用耦合模拟立柱导轨之间的连接;螺钉采用三个方向的非线性弹簧单元(Spring2)模拟墙面板与轻钢骨架的连接.根据试验现象和数据,螺钉在三个方向的荷载![]() 位移都各不相同,本文主要以加载方向(z轴)的滑移破坏为准则,连接强度的定义参考文献[2-4].

位移都各不相同,本文主要以加载方向(z轴)的滑移破坏为准则,连接强度的定义参考文献[2-4].

1.3 试验与数值计算结果对比

1.3.1 特征参数的确定

为了便于分析,对荷载![]() 变形关系曲线做特征化处理.弹性刚度Ke参照标准ECCS,取0.4倍峰值荷载Pm处割线刚度;屈服点参照《建筑抗震试验规程》(JGJ/T101-2015)确定.

变形关系曲线做特征化处理.弹性刚度Ke参照标准ECCS,取0.4倍峰值荷载Pm处割线刚度;屈服点参照《建筑抗震试验规程》(JGJ/T101-2015)确定.

1.3.2 结果对比分析

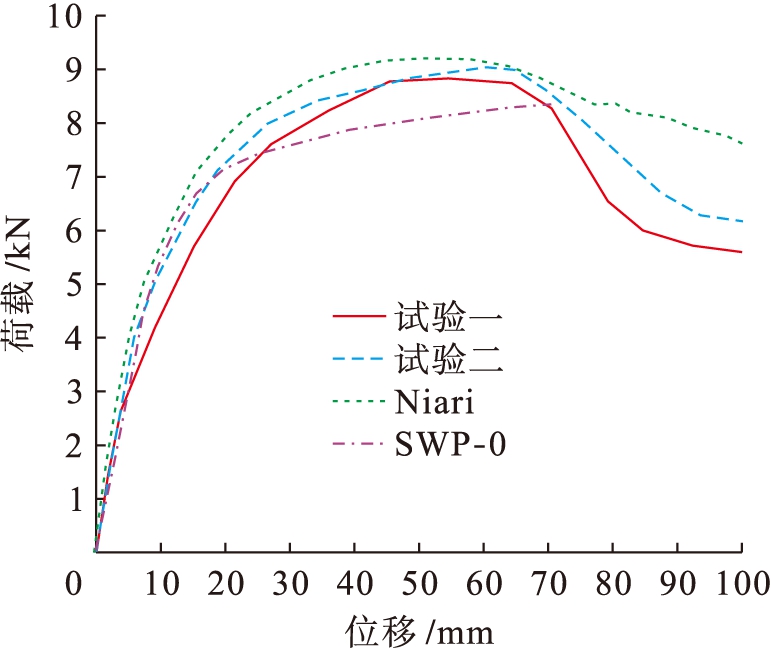

计算结果如图1所示.从图1中可以看出,Niari的数值模拟和SWP-0数值模拟在加载初期曲线呈线性分布,组合墙体基本处于弹性阶段.继续加载至曲线出现明显的拐点时,说明墙面板底部螺钉已达到极限强度(非线性弹簧单元).从单位抗剪承载力的对比来看,SWP-0与试验一和试验二的误差约在6%,虽然取得最大荷载时对应的位移不同,但承载力基本吻合.

图1 试验与数值模拟的组合墙荷载-位移曲线

Fig.1 Loading-displacement curves of composite walls by experimental measuring and numerical modeling

2 墙体有限元模型参数分析

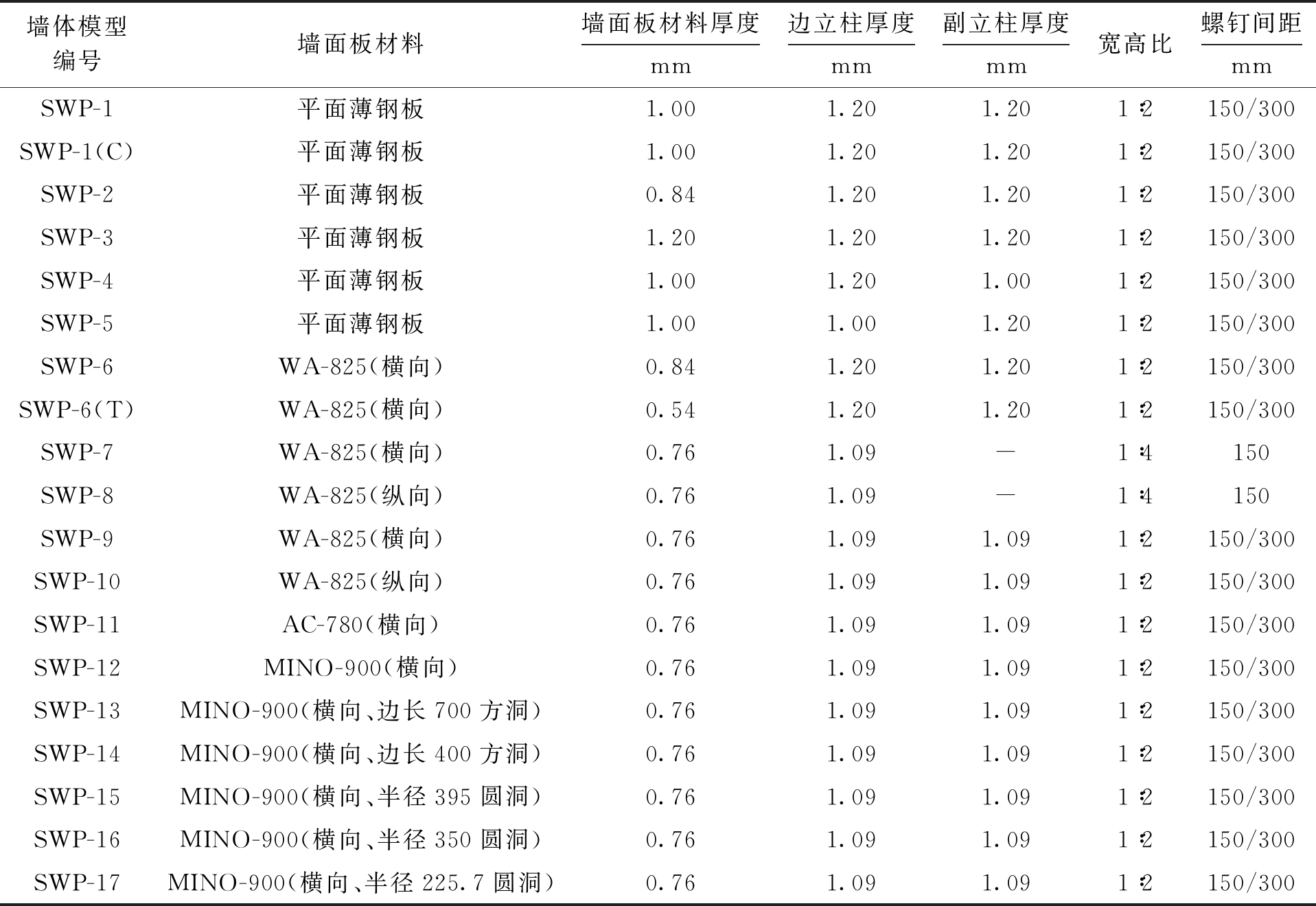

进行有限元计算模型参数分析时,所有骨架构件钢材选用Q345,SWP-1~SWP-6包括SWP-1(C)和SWP-6(T)的墙面板材料选用Q345,SWP-7~SWP-17的墙面板材料选用Q235;组合墙C型立柱和U型导轨的截面尺寸均为C152.4 mm×41.15 mm×12.7 mm和U152.4 mm×41.15 mm,具体模型参数如表3所示.

2.1 薄钢板厚度对组合墙抗剪性能的影响

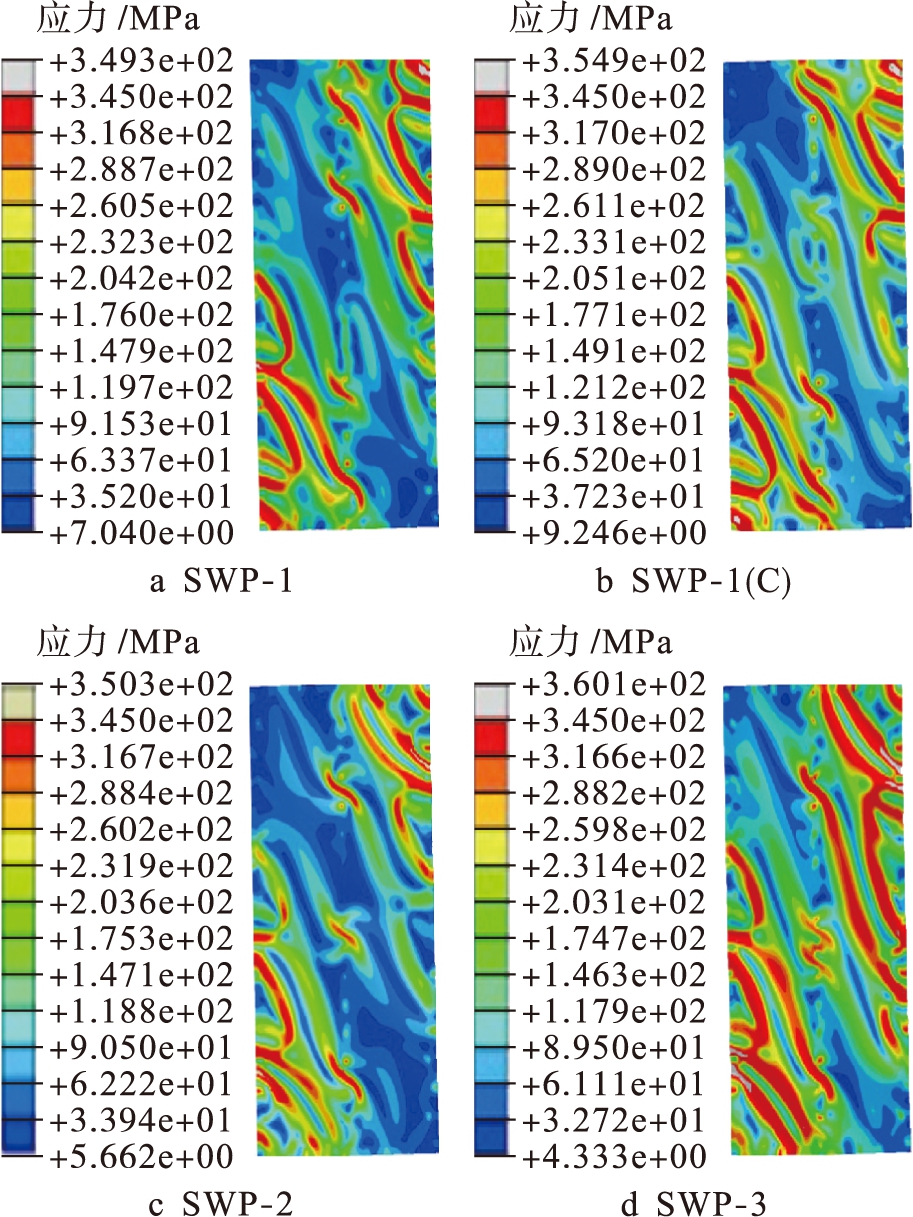

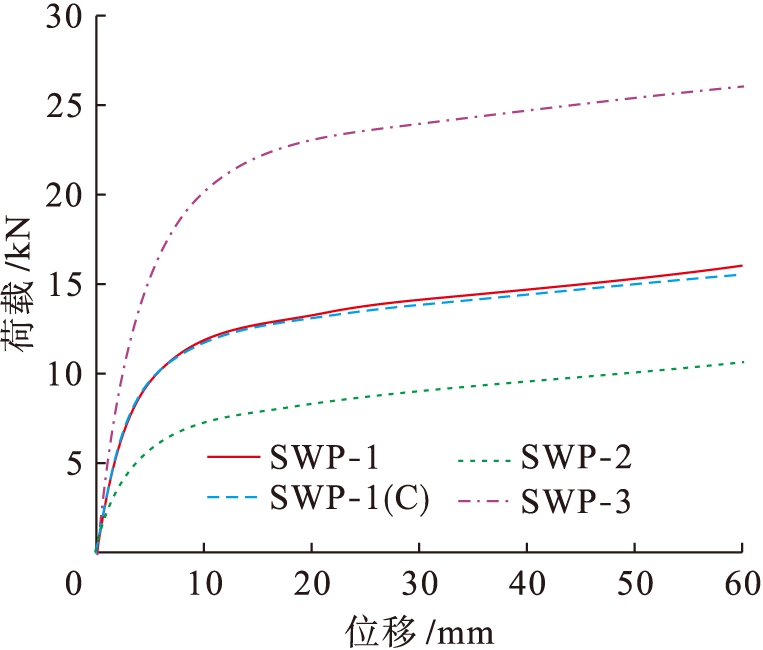

0.84、1.00和1.2 mm厚平面薄钢板覆面组合墙有限元计算结果,如图2、3和表4所示.随着墙面板厚度增大,1.00和1.20 mm厚平面薄钢板覆面组合墙的单位抗剪承载力分别比0.84 mm厚墙面板提高了48.58%和141.34%,初始刚度分别提高了61.31%和136.68%,可见平面薄钢板厚度对组合墙承载力和初始刚度有显著影响,此影响因素也包括了随着薄钢板厚度增加而增加的连接强度的影响;立柱翼缘截面为弧形的SWP-1(C),初始刚度和抗剪承载力无明显变化.

表3 有限元模型参数

Tab.3 Parameters for finite element model

墙体模型编号墙面板材料墙面板材料厚度mm边立柱厚度mm副立柱厚度mm宽高比螺钉间距mmSWP-1平面薄钢板1.001.201.201∶2150/300SWP-1(C)平面薄钢板1.001.201.201∶2150/300SWP-2平面薄钢板0.841.201.201∶2150/300SWP-3平面薄钢板1.201.201.201∶2150/300SWP-4平面薄钢板1.001.201.001∶2150/300SWP-5平面薄钢板1.001.001.201∶2150/300SWP-6WA-825(横向)0.841.201.201∶2150/300SWP-6(T)WA-825(横向)0.541.201.201∶2150/300SWP-7WA-825(横向)0.761.09-1∶4150SWP-8WA-825(纵向)0.761.09-1∶4150SWP-9WA-825(横向)0.761.091.091∶2150/300SWP-10WA-825(纵向)0.761.091.091∶2150/300SWP-11AC-780(横向)0.761.091.091∶2150/300SWP-12MINO-900(横向)0.761.091.091∶2150/300SWP-13MINO-900(横向、边长700方洞)0.761.091.091∶2150/300SWP-14MINO-900(横向、边长400方洞)0.761.091.091∶2150/300SWP-15MINO-900(横向、半径395圆洞)0.761.091.091∶2150/300SWP-16MINO-900(横向、半径350圆洞)0.761.091.091∶2150/300SWP-17MINO-900(横向、半径225.7圆洞)0.761.091.091∶2150/300

图2 墙面板应力云图(1)

Fig.2 Stress nephogram of wall panels (1)

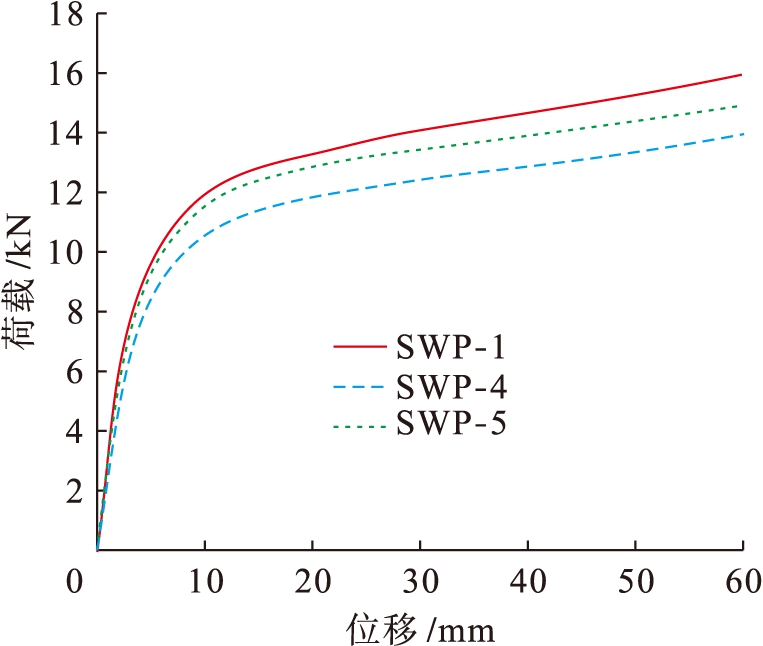

2.2 立柱厚度对组合墙抗剪性能的影响

立柱厚度和截面对组合墙抗剪性能的影响,如图4和表5所示.相比SWP-1,SWP-4和SWP-5单位抗剪承载力分别下降12.42%和6.78%,SWP-4初始刚度下降14.64%,而SWP-5提高1.56%,由此说明,立柱厚度对组合墙抗剪承载力和初始刚度无明显影响.

图3 组合墙荷载![]() 位移对比图(1)

位移对比图(1)

Fig.3 Load-displacement comparison of composite walls (1)

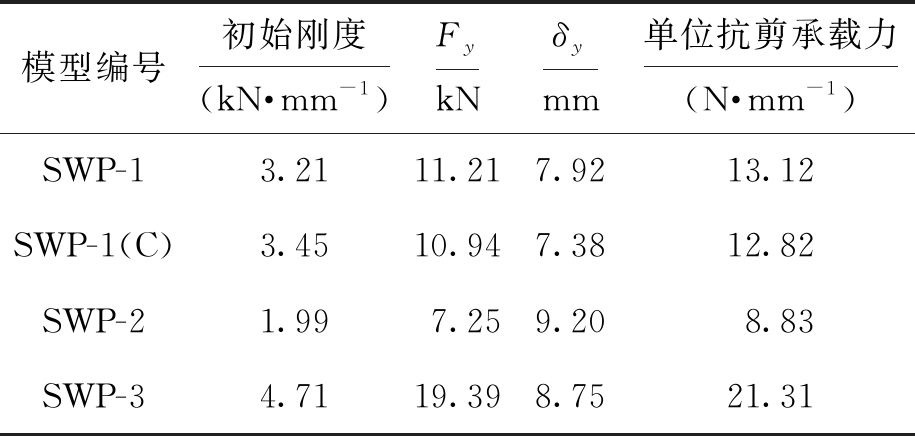

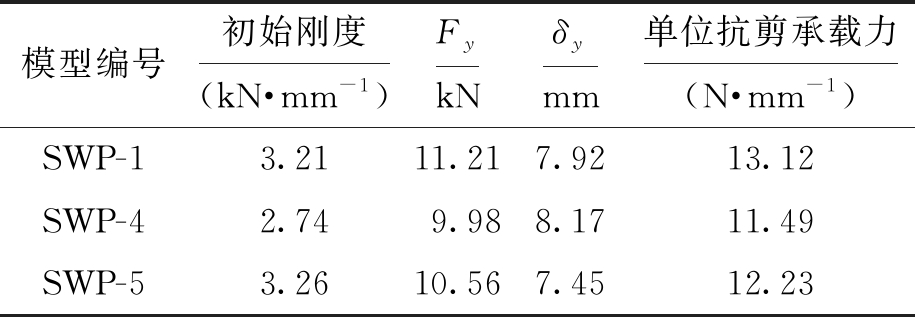

表4 模拟值数据对比(1)

Tab.4 Comparison of simulated data (1)

模型编号初始刚度(kN·mm-1)FykNδymm单位抗剪承载力(N·mm-1)SWP-13.2111.217.9213.12SWP-1(C)3.4510.947.3812.82SWP-21.997.259.208.83SWP-34.7119.398.7521.31

注:Fy为屈服承载力;δy为屈服承载力对应位移.

图4 组合墙荷载![]() 位移对比图(2)

位移对比图(2)

Fig.4 Load-displacement comparison of composite walls (2)

表5 模拟值数据对比(2)

Tab.5 Comparison of simulated data (2)

模型编号初始刚度(kN·mm-1)FykNδymm单位抗剪承载力(N·mm-1)SWP-13.2111.217.9213.12SWP-42.749.988.1711.49SWP-53.2610.567.4512.23

2.3 墙面板几何形式对组合墙抗剪性能的影响

波纹钢板因其几何外形,提供了一定的刚度,使得覆面波纹钢板不易屈曲,可有效提高构件的屈曲性能,使墙体承担较大的轴压力、弯矩或剪力而不屈曲.

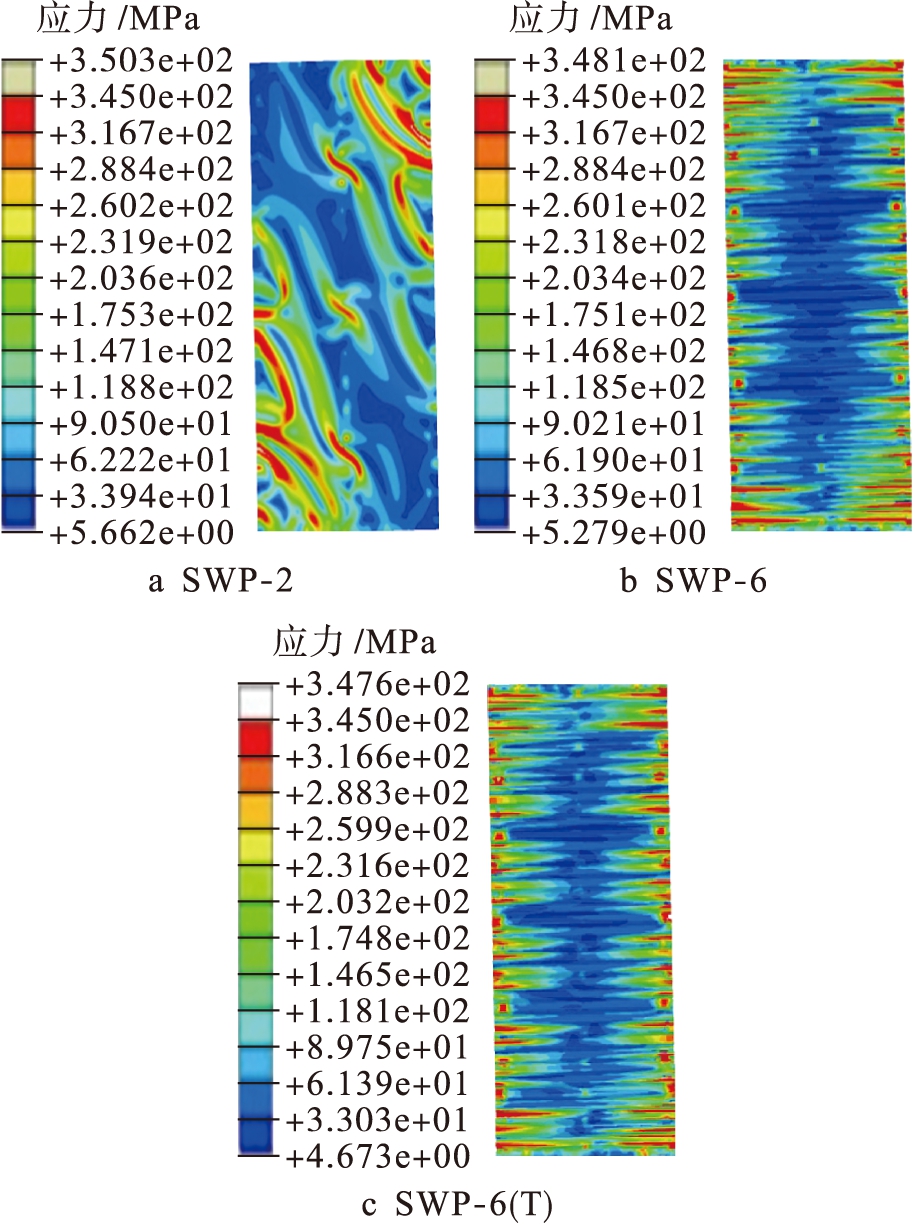

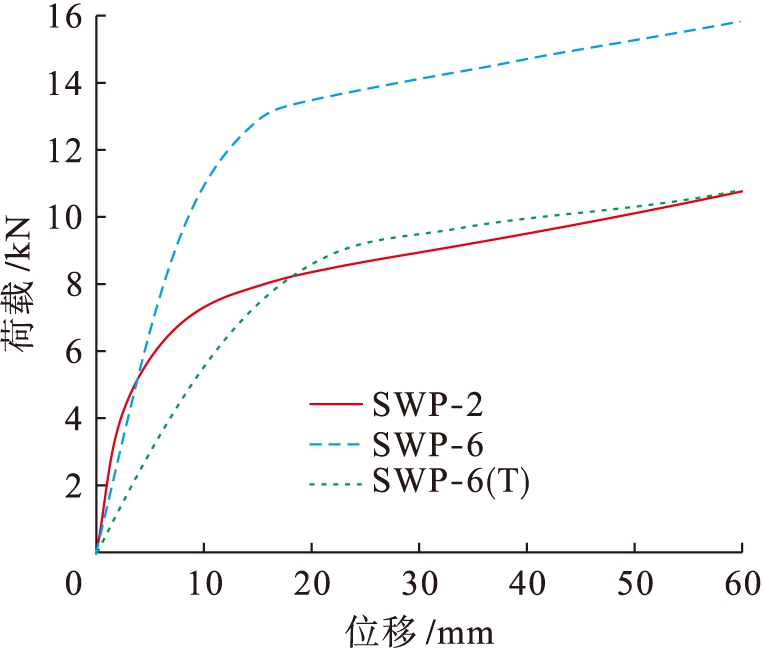

2.3.1 波纹板与平面薄钢板组合墙抗剪性能比较

平面薄钢板覆面组合墙与波纹钢板覆面组合墙对比计算结果如图5、6和表6所示.相较于SWP-2,比其覆面钢板等厚度的SWP-6的单位抗剪承载力提高了46.89%,初始刚度下降27.64%,而与SWP-2承载力相当的SWP-6(T)的覆面钢板厚度只有SWP-2覆面钢板厚度的64.29%,但初始刚度大幅下降.

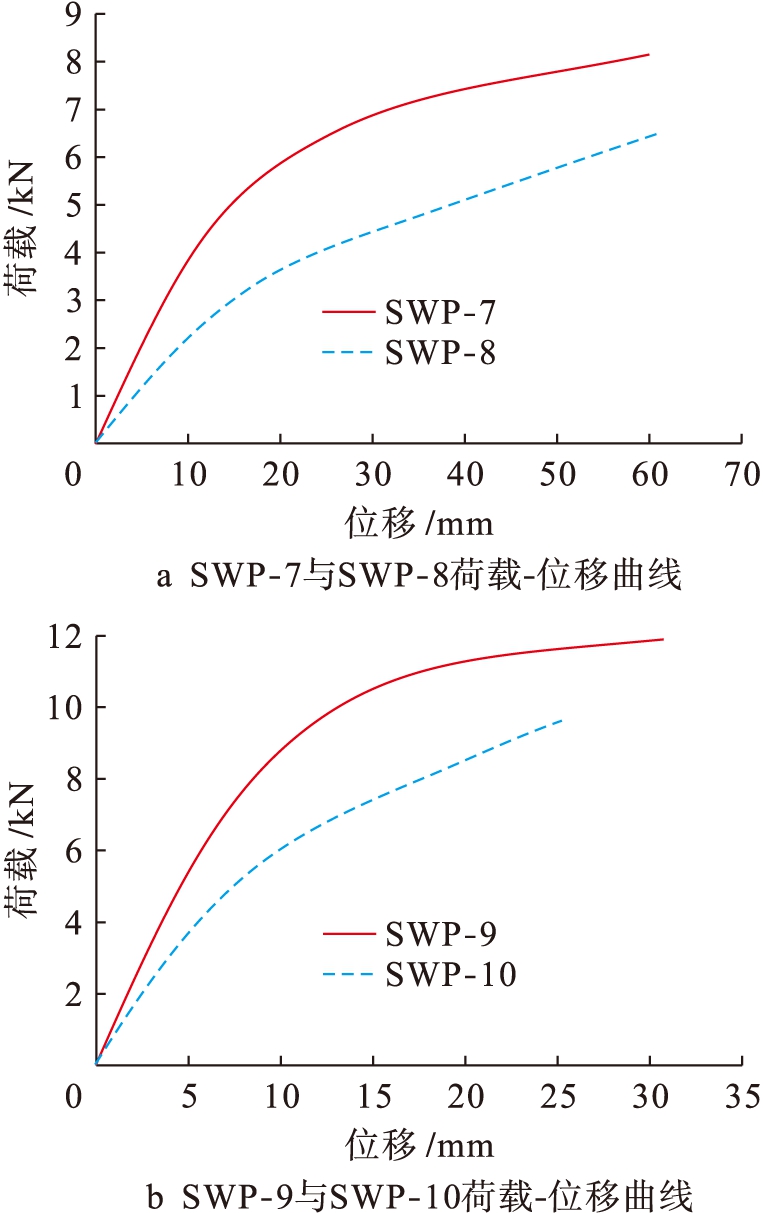

2.3.2 布置方向和高宽比对组合墙抗剪性能影响

计算结果如图7、8和表7所示.高宽比为4∶1时,SWP-7比SWP-8承载力提高了26.45%,初始刚度提高85.71%;高宽比为2∶1时,SWP-9比SWP-10承载力提高了17.82%,初始刚度提高了46.10%.在两种高宽比下,横向波纹覆面组合墙承载力和初始刚度均高于纵向波纹覆面组合墙.

图5 墙面板应力云图(2)

Fig.5 Stress nephogram of wall panels (2)

图6 组合墙荷载![]() 位移对比图(3)

位移对比图(3)

Fig.6 Load-displacement comparison of composite walls (3)

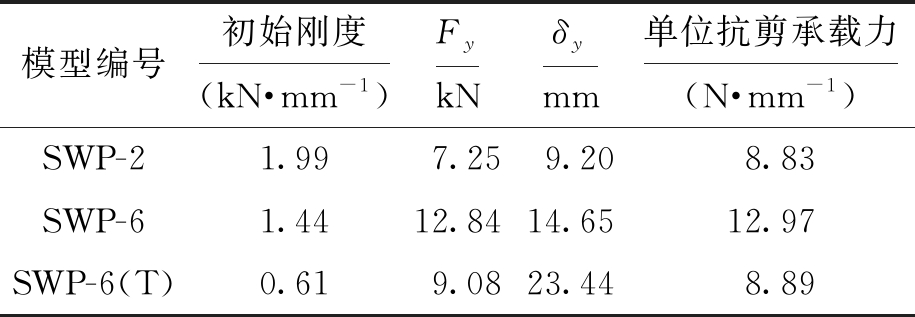

表6 模拟值数据对比(3)

Tab.6 Comparison of simulated data (3)

模型编号初始刚度(kN·mm-1)FykNδymm单位抗剪承载力(N·mm-1)SWP-21.997.259.208.83SWP-61.4412.8414.6512.97SWP-6(T)0.619.0823.448.89

随着高宽比的减小,初始刚度逐渐增大,SWP-9比SWP-7高184.62%,SWP-10比SWP-8高261.90%,而单位抗剪承载力却下降,SWP-9比SWP-7下降29.38%,SWP-10比SWP-8下降24.20%,随着高宽比的减小,组合墙初始刚度大幅提高,单位抗剪承载力略有下降.

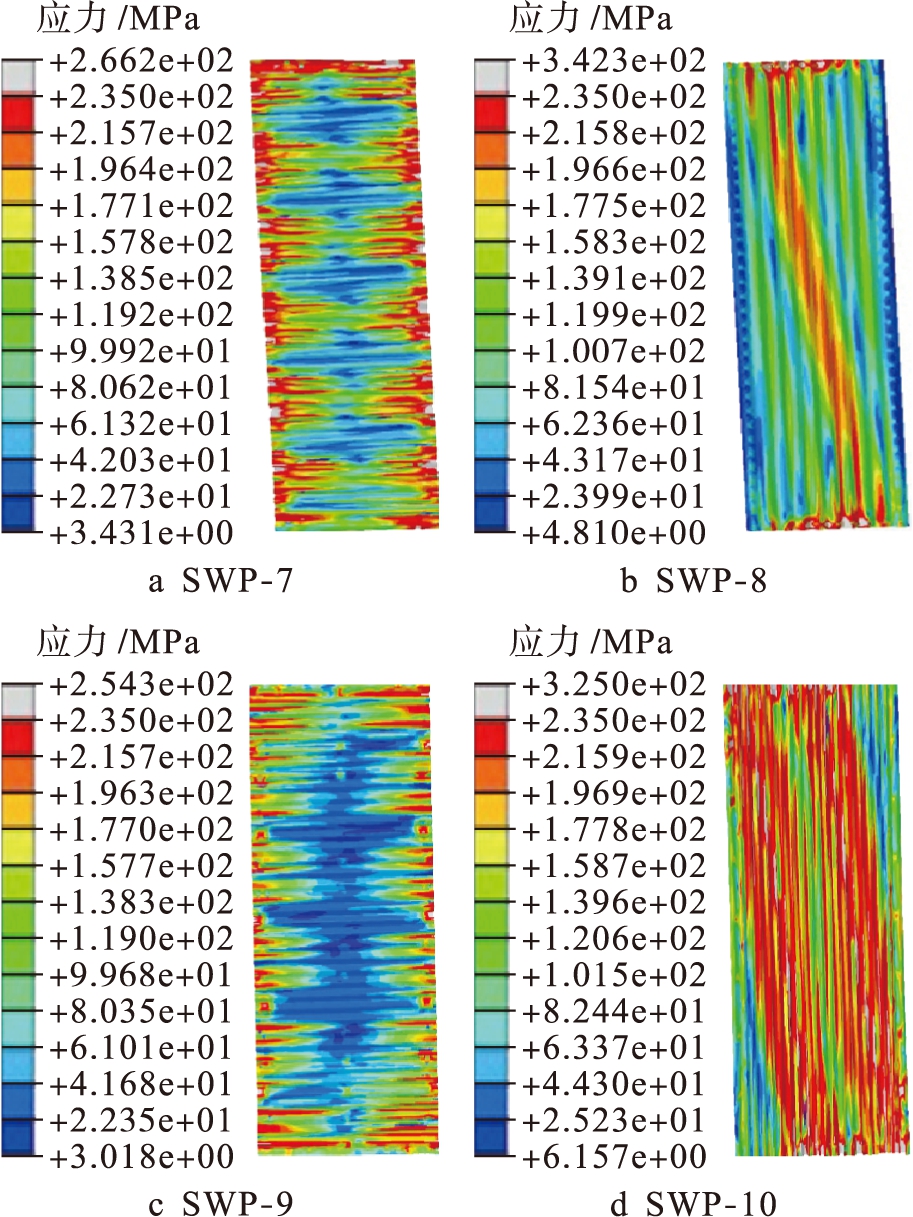

图7 墙面板应力云图(3)

Fig.7 Stress nephogram of wall panels (3)

图8 组合墙荷载![]() 位移对比图(4)

位移对比图(4)

Fig.8 Load-displacement comparison of composite walls (4)

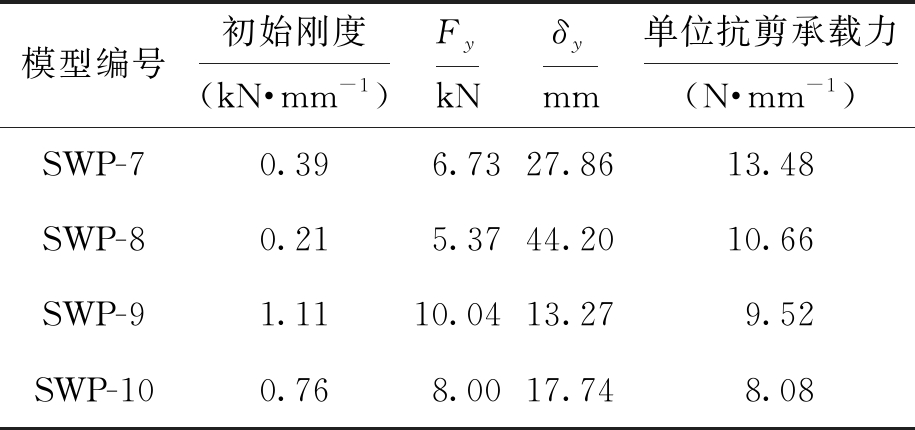

表7 模拟值数据对比(4)

Tab.7 Comparison of simulated data (4)

模型编号初始刚度(kN·mm-1)FykNδymm单位抗剪承载力(N·mm-1)SWP-70.396.7327.8613.48SWP-80.215.3744.2010.66SWP-91.1110.0413.279.52SWP-100.768.0017.748.08

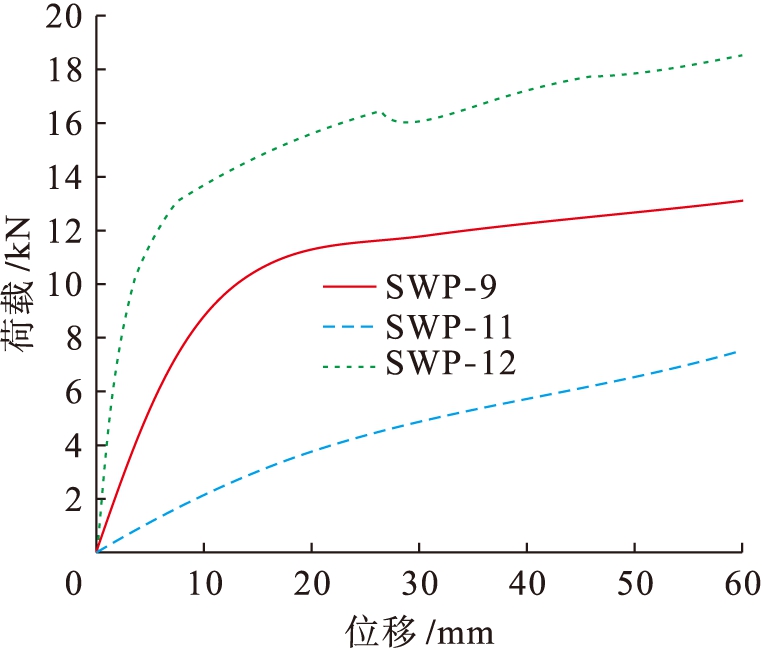

2.3.3 不同类型波纹板对组合墙抗剪性能影响

不同类型波纹板覆面组合墙计算结果如图9和表8所示.相较于WA-825波纹板覆面组合墙,MINO-900波纹板覆面组合墙的单位抗剪承载力和初始刚度分别提高约60%和200%,AC-780波纹板覆面组合墙的单位抗剪承载力和初始刚度分别下降35%和80%.随着波长和波幅的减小,组合墙承载力、初始刚度增大,屈服位移减小.

图9 组合墙荷载![]() 位移对比图(5)

位移对比图(5)

Fig.9 Load-displacement comparison of composite walls (5)

表8 模拟值数据对比(5)

Tab.8 Comparison of simulated data (5)

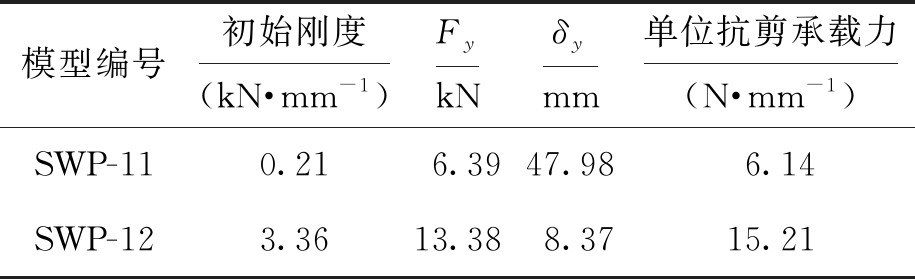

模型编号初始刚度(kN·mm-1)FykNδymm单位抗剪承载力(N·mm-1)SWP-110.216.3947.986.14SWP-123.3613.388.3715.21

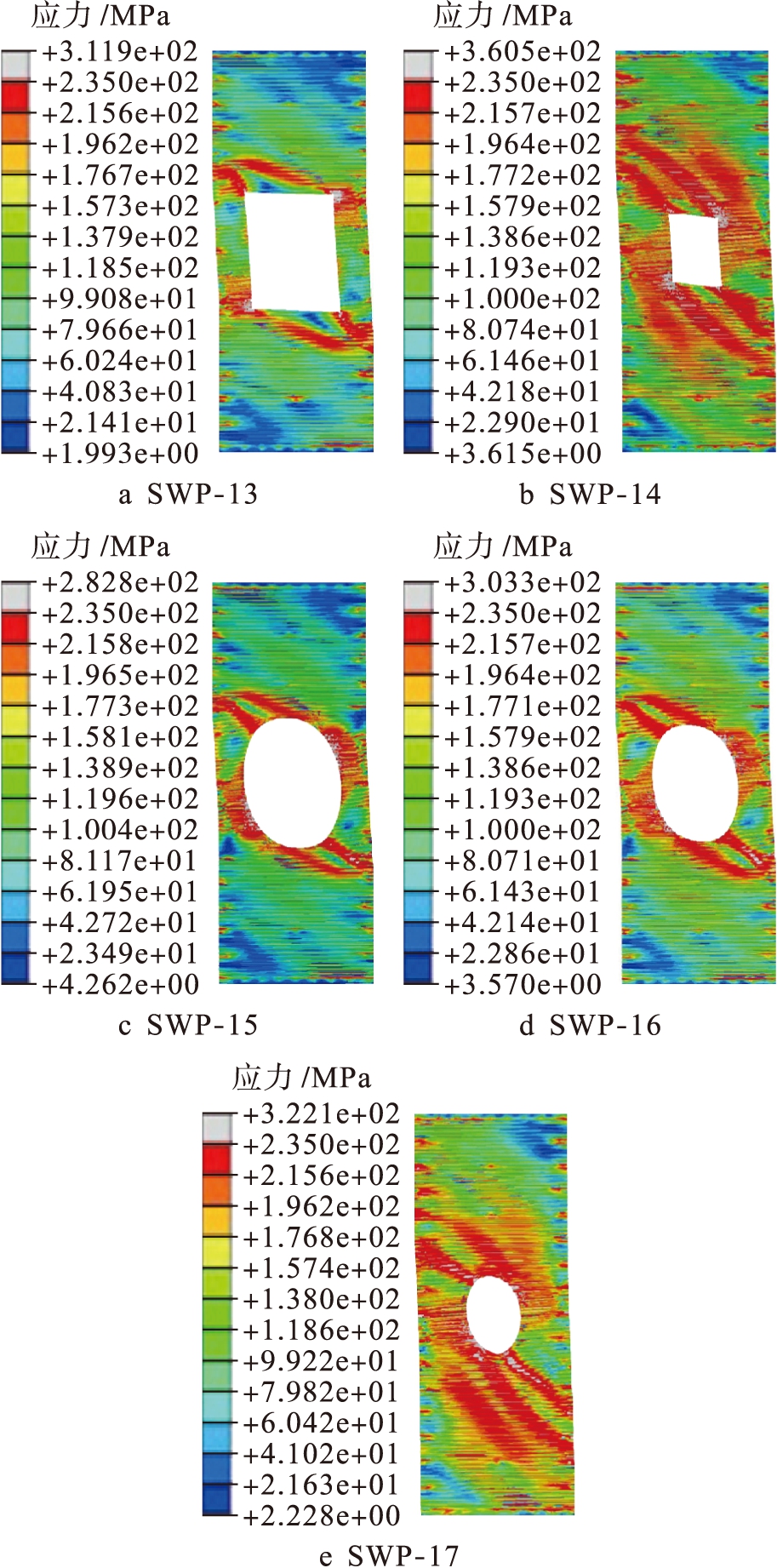

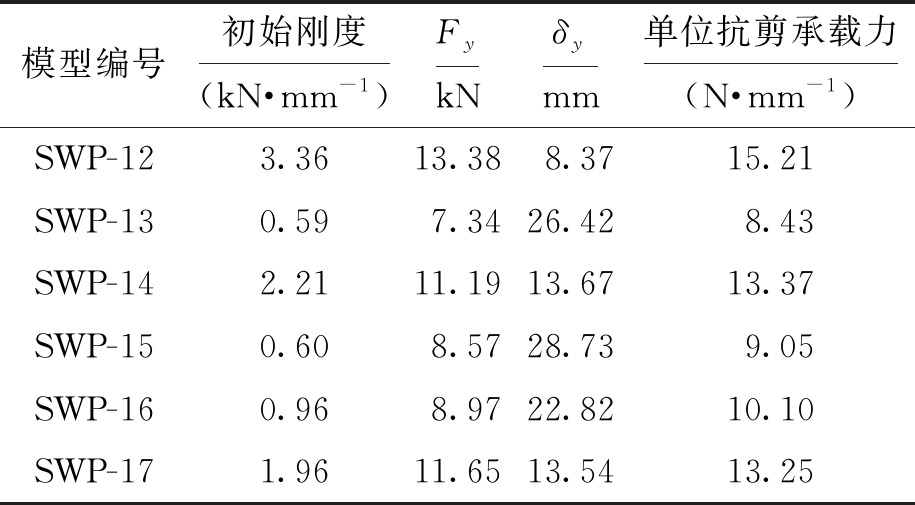

2.3.4 波纹板开洞对组合墙抗剪性能影响

波纹钢板覆面组合墙提高了平面内稳定性,但过大的刚度延性较差,抗震耗能较低.本文有限元分析中墙面板洞口均位于墙体形心,其中,SWP-15圆洞的面积等于SWP-13方洞的面积,SWP-16圆洞的直径等于SWP-13方洞的边长,SWP-17圆洞的面积等于SWP-14方洞的面积.

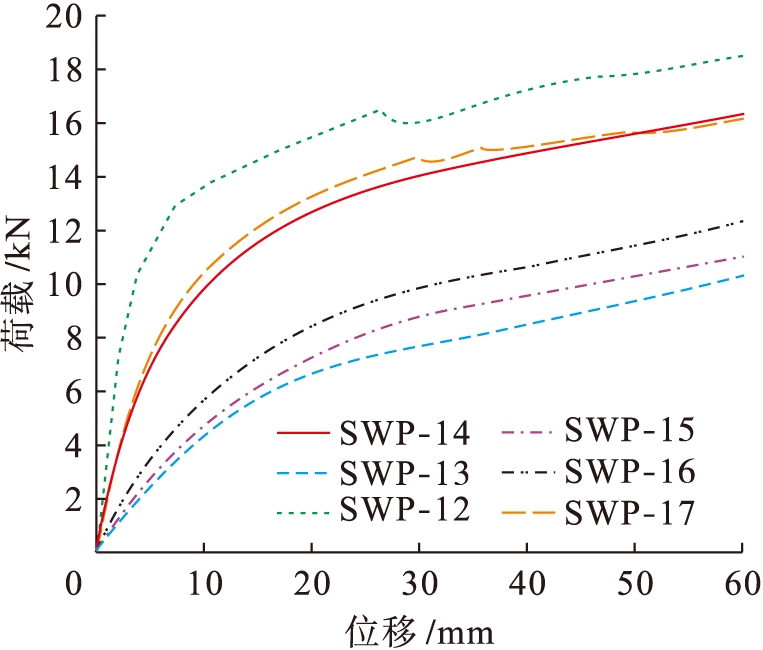

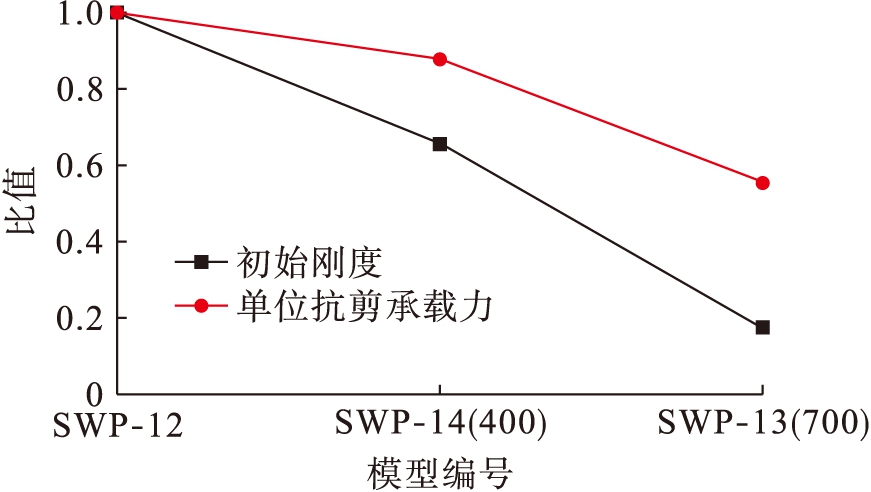

计算结果如图10~12和表9所示.随着方洞尺寸的增大,初始刚度和单位抗剪承载力的下降幅度增大,相较于SWP-12,SWP-13初始刚度降低了约80%,但组合墙的单位抗剪承载力同时下降了约45%,下降幅度较大;相较于SWP-12,SWP-14初始刚度降低约35%,单位抗剪承载力降低12%.

图10 墙面板应力云图(4)

Fig.10 Stress nephogram of wall panels (4)

相比SWP-13,SWP-15(圆洞面积等于SWP-13)单位抗剪承载力提高约8%,两者初始刚度相当,SWP-16圆洞的面积小于SWP-15,且直径等于SWP-13方洞边长,其初始刚度提高约60%,单位抗剪承载力提高约20%;相较SWP-14,SWP-17(圆洞面积等于SWP-14)初始刚度下降10%,两者承载力相当.方洞与圆洞对组合墙抗剪性能的影响无明显差异,而洞口面积对组合墙抗剪性能影响显著.

图11 组合墙荷载![]() 位移对比图(6)

位移对比图(6)

Fig.11 Load-displacement comparison of composite walls (6)

图12 不同方洞尺寸的特征参数对比

Fig.12 Comparison of characteristic paramaters of square hole with different sizes

表9 模拟值数据对比(6)

Tab.9 Comparison of simulated data (6)

模型编号初始刚度(kN·mm-1)FykNδymm单位抗剪承载力(N·mm-1)SWP-123.3613.388.3715.21SWP-130.597.3426.428.43SWP-142.2111.1913.6713.37SWP-150.608.5728.739.05SWP-160.968.9722.8210.10SWP-171.9611.6513.5413.25

3 结 论

本文采用ABAQUS对冷弯薄壁型钢组合墙进行了参数分析,得到的结论如下:

1) 平面薄钢板墙体承载力和初始刚度随着板厚增大而显著提高,立柱壁厚及弧形翼缘截面边立柱对组合墙抗剪性能无明显影响.

2) 相同厚度下(0.84 mm),WA-825波纹板组合墙单位抗剪承载力比平面薄钢板组合墙高约45%,初始刚度无明显变化,承载力相当时,波纹板厚约为平面薄钢板的65%;横向波纹板组合墙承载力和初始刚度均高于纵向波纹板组合墙,且随着高宽比从4∶1(2 440 mm×610 mm)下降至2∶1(2 440 mm×1 220 mm)时,单位抗剪承载力略有下降,而初始刚度大幅提高.

3) 通过MINO-900波纹板组合墙的研究和分析,圆洞和方洞对组合墙抗剪性能的影响无明显差异,而开洞面积对其影响显著.

[1]黄智光.低层冷弯薄壁型钢房屋抗震性能研究 [D].西安:西安建筑科技大学,2011.

(HUANG Zhi-guang.Seismic behaviors study on low-rise cold-formed thin-wall steel residential buildings [D].Xi’an:Xi’an University of Architecture and Technology,2011.)

[2]李元齐,马荣奎,何慧文.冷弯薄壁型钢与覆面钢板自攻螺钉连接性能试验研究 [J].建筑钢结构进展,2017,19(6):60-64.

(LI Yuan-qi,MA Rong-kui,HE hui-wen.Experimental study on behavior of screw connections for cold-formed thin-walled steel studs and steel sheathings [J].Progress in Steel Building Structures,2017,19(6):60-64.)

[3]石宇,王身伟,刘永健,等.冷弯薄壁型钢单颗自攻螺钉抗剪连接性能研究 [J].建筑科学与工程学报,2014,31(2):57-64.

(SHI Yu,WANG Shen-wei,LIU Yong-jian,et al.Research on shear behavior of single tapping screw connection in cold-formed thin-wall steel structures [J].Journal of Architecture and Civil Engineering,2014,31(2):57-64.)

[4]李元齐,马荣奎,宋延勇,等.冷弯薄壁型钢螺钉连接抗剪性能试验研究 [J].同济大学学报,2013,41(1):11-19.

(LI Yuan-qi,MA Rong-kui,SONG Yan-yong,et al.Experimental study on shear behavior of screw con-nections for cold-formed thin-walled steel structures [J].Journal of Tongji University,2013,41(1):11-19.)

[5]刘朋,徐敬文,宁宝宽,等.OSB板纹理对连接性能的影响 [J].沈阳工业大学学报,2017,39(3):357-360.

(LIU Peng,XU Jing-wen,NING Bao-kuan,et al.In-fluence of OSB texture on connection performance [J].Journal of Shenyang University of Technology,2017,39(3):357-360.)

[6]Tian Y S,Wang J,Lu T J.Racking strength and stiffness of cold-formed steel wall frames [J].Journal of Construction Steel Research,2004,60(7):1069-1093.

[7]Serrette R L,Lam I,Qi H.Cold-formed steel frame shear walls utilizing structural adhesives [J].Journal of Structural Engineering,2006,132(4):591-599.

[8]Balh N.Development of seismic design provisions for steel sheathed shear walls[R].Montreal:McGill University,2011.

[9]Niari S E,Rafezy B,Abedi K.Numerical modeling and finite element analysis of steel sheathed cold-formed steel shear walls [J].Steel and Composite Structures,2016,22(1):79-89.